Ağu . 13, 2025 03:40 Back to list

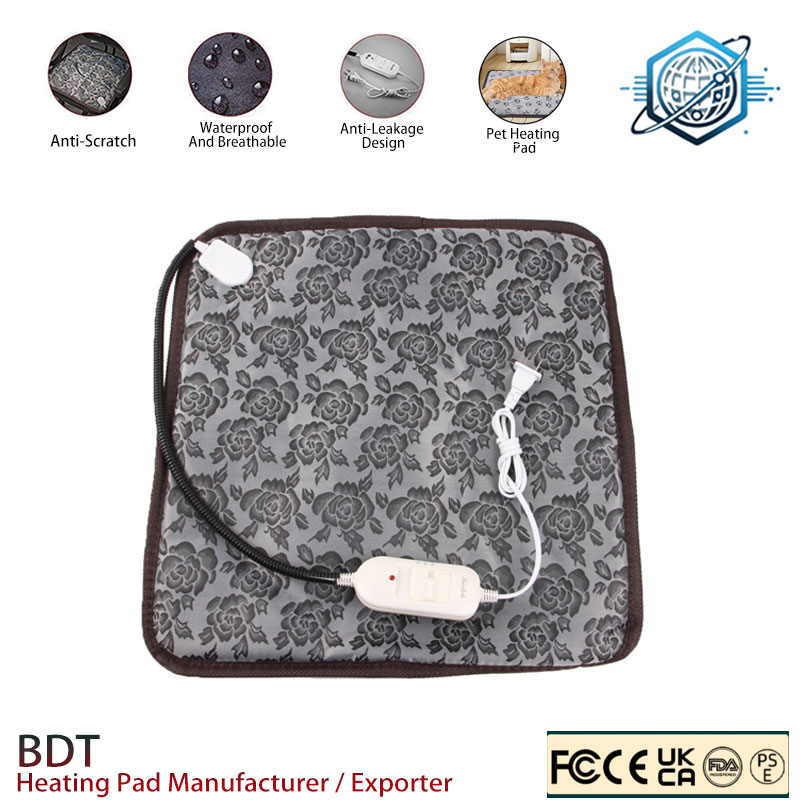

Ultimate Pet Heating Pad: Waterproof, Automatic, All Sizes

The Evolution of Pet Comfort: Understanding Advanced Heating Pad Technologies

In the rapidly expanding pet care market, advanced solutions for animal welfare are paramount. Among these, the pet heating pad stands out as a critical component for ensuring the comfort, health, and recovery of companion animals. From domestic settings to professional veterinary clinics and animal shelters, these devices provide essential thermoregulation, crucial for young, elderly, ill, or recovering pets. The demand for reliable, safe, and efficient heating solutions has driven significant innovation in design, material science, and safety features, addressing the diverse needs of pets ranging from small rodents to large dog breeds. This comprehensive overview delves into the technical intricacies, application versatility, and strategic advantages of modern pet heating solutions.

The market is witnessing a strong trend towards specialized products, including the demand for a reliable outdoor pet heating pad designed to withstand varying environmental conditions, alongside sophisticated indoor pet heating pad models that seamlessly blend into home environments. Veterinary professionals and animal care facilities are increasingly seeking robust, easy-to-clean, and highly controllable units that can support post-operative recovery or provide therapeutic warmth.

Manufacturing Excellence: Crafting a Superior Pet Heating Pad

The production of a high-quality pet heating pad involves a meticulous multi-stage manufacturing process, emphasizing durability, safety, and consistent performance. The core components typically include advanced heating elements, often made from carbon fiber or PVC-insulated alloy wires, chosen for their rapid and uniform heat distribution. These elements are securely laminated between layers of fire-retardant PVC or durable, soft textile fabrics. The outer cover is frequently crafted from robust, chew-resistant materials like oxford fabric or soft fleece, chosen for both comfort and ease of cleaning, with options for a waterproof pet heating pad utilizing high-frequency welding to seal seams against moisture ingress.

Key manufacturing processes include automated lamination for consistent bonding of heating elements to substrate materials, precision cutting using CNC machinery for accurate sizing (from small pet heating pad to large pet heating pad dimensions), and ultrasonic welding for creating impermeable seals in waterproof models. The integrated control units, often featuring an automatic pet heating pad function or a pet heating pad with timer, undergo injection molding for their casings, ensuring robust protection for sensitive electronics. Adherence to strict inspection standards such as ISO 9001 for quality management and rigorous electrical safety certifications like UL, CE, and RoHS is paramount throughout the production cycle. Products undergo thermal testing using NTC thermistors for precise temperature control, pressure testing to ensure structural integrity, and electrical leakage testing to guarantee user and pet safety. The typical design life for a well-manufactured unit can exceed 5-7 years, even under continuous use, making them a cost-effective solution for long-term applications.

These specialized manufacturing techniques ensure the finished product's reliability and safety. For instance, the use of PTC (Positive Temperature Coefficient) heating elements in some designs provides self-regulating temperature control, minimizing the risk of overheating without complex external controls. This advanced engineering focus translates into significant advantages in typical application scenarios, including enhanced energy efficiency compared to less sophisticated designs, superior uniform heating performance across the entire pad surface, and robust resistance to wear and tear from pet activity, offering a truly durable solution for both residential and commercial use cases.

Technical Specifications and Performance Metrics

Selecting the appropriate pet heating pad requires a comprehensive understanding of its technical specifications. Key parameters directly influence performance, safety, and suitability for various applications. For example, voltage options cater to different power sources, with a 12v pet heating pad or 12 volt pet heating pad being ideal for portable or vehicle-based applications, while standard AC voltage models (120V/230V) are common for home and clinic use. Wattage determines heat output and energy consumption, with higher wattages generally providing more intense heat, crucial for larger pets or colder environments.

| Parameter | Description | Common Range/Value |

|---|---|---|

| Voltage Input | Operating voltage compatible with power source. | DC 12V, AC 120V, AC 230V |

| Power Output (Wattage) | Heat generation capacity. | 15W - 80W (depending on size) |

| Temperature Range | Adjustable temperature settings. | 30°C - 50°C (86°F - 122°F) |

| IP Rating | Ingress Protection against solids and liquids. | IPX4 (splash-proof) to IP67 (submersible) |

| Cable Length | Length of power cord, often chew-resistant. | 1.5m - 2.5m (60-100 inches) |

| Safety Features | Built-in protective mechanisms. | Overheat protection, thermal fuse, chew-resistant cord, low voltage (for 12V) |

| Material | Primary materials for pad and cover. | PVC, Oxford Fabric, Fleece, Carbon Fiber Heating Elements |

Understanding these parameters is crucial for B2B buyers seeking bulk orders or customized solutions. For instance, an outdoor pet heating pad requires a higher IP rating (e.g., IP67) for superior water resistance and enhanced durability against environmental elements, whereas an indoor pet heating pad might prioritize soft materials and aesthetic design. The integration of advanced features such as microchip-controlled thermostats, thermal fuses for short-circuit protection, and durable chew-resistant cords significantly enhances both the safety and longevity of the product, providing peace of mind for both the end-user and the distributing business.

Diverse Applications and Key Advantages

The versatility of a well-engineered pet heating pad extends across a myriad of applications, directly contributing to animal welfare and operational efficiency in professional settings. For instance, veterinary clinics heavily rely on these pads for post-operative recovery, aiding in temperature regulation and pain management for animals recovering from surgery. The gentle, consistent warmth provided by an Electric Cat Dog Heating Pad can alleviate joint pain and stiffness in older animals, making them an indispensable tool for geriatric pet care. In breeding facilities, specialized pet heating pads for dogs and pet heating pads for cats are vital for maintaining optimal temperatures for newborns and their mothers, crucial for survival and healthy development, particularly for smaller breeds prone to hypothermia.

Beyond clinical and breeding environments, the utility of these pads extends to animal shelters and rescue organizations, where outdoor pet heating pad models provide essential warmth in colder climates, protecting animals from frostbite and maintaining their core body temperature. For home users, particularly those with a large pet heating pad, it offers a designated warm spot for their furry companions during chilly seasons, enhancing overall pet comfort and well-being. The inherent advantages include significant energy savings through targeted heating, superior safety features that prevent overheating or electrical hazards, and exceptional durability, ensuring a long operational lifespan even under heavy use. Furthermore, features like an automatic pet heating pad with a built-in thermostat ensure consistent warmth without manual adjustments, while a pet heating pad with timer allows for scheduled heating cycles, optimizing energy use and convenience.

The focus on user-friendliness and low maintenance, particularly with options like machine-washable covers for optimal hygiene, further enhances their appeal across all application sectors. For example, a cordless pet heating pad provides ultimate flexibility for mobile pet care services or areas without direct power outlets, demonstrating the industry's commitment to addressing diverse market needs with innovative solutions.

Manufacturer Comparison & Customization Solutions

In the competitive landscape of pet heating pad manufacturing, distinguishing factors often come down to R&D capability, quality assurance, and the flexibility for customization. Leading manufacturers, such as BDTHD, differentiate themselves through a robust commitment to innovation, evidenced by patents on heating element technology and advanced safety circuits. Unlike general electronics manufacturers, specialized heating pad producers focus intensely on the unique physiological needs of pets and the practical demands of their caretakers. This includes specific temperature ranges optimized for animal comfort and recovery, rather than human preferences, and enhanced durability against common pet behaviors like chewing or scratching.

A key advantage offered by expert manufacturers is the ability to provide extensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This allows B2B clients to tailor products precisely to their market's demands, whether it's specific dimensions for a pet heating pad large enough for giant breeds, integrating unique branding, or developing specific functionalities like enhanced temperature precision or integrated smart home connectivity. Manufacturers with extensive service years and high production volumes often have stringent quality control systems, including ISO-certified testing labs and partnerships with international safety certification bodies like UL, CE, and GS. This level of quality assurance is a crucial factor for distributors and retailers looking for reliable, compliant products that build consumer trust.

Choosing a manufacturer with proven expertise in heating technology and a strong track record in pet care product innovation ensures access to cutting-edge solutions that meet evolving market needs. Their technical teams can provide invaluable support in product development, material selection, and compliance, making the partnership a strategic asset for businesses aiming for market leadership in pet comfort products. This collaborative approach fosters the creation of truly exceptional and market-relevant pet heating pads.

Building Trust: FAQs, Delivery, and Warranty

Transparency and robust customer support are cornerstones of trustworthiness in the B2B sector. For the Electric Cat Dog Heating Pad, common queries often revolve around safety, power consumption, and cleaning. Addressing these proactively, a typical pet heating pad is designed with multi-layer safety features, including an internal thermal fuse, temperature control chip (NTC thermistor), and often a low-voltage transformer for enhanced safety, especially for 12v pet heating pad models. Power consumption is generally low, ranging from 15W to 80W, depending on size and settings, making them energy-efficient for continuous use. Most pads feature removable, machine-washable covers, while the main pad can be wiped clean, ensuring hygiene and longevity.

Frequently Asked Questions (FAQs)

- Q: Are these pet heating pads safe for continuous use?

A: Yes, our Electric Cat Dog Heating Pads are equipped with multiple safety features, including internal thermostats and overheat protection systems, making them safe for continuous, monitored use. - Q: What is the average delivery time for bulk orders?

A: Standard lead times for bulk orders typically range from 20-35 business days, depending on order volume and customization requirements. Expedited options are available upon request. - Q: Do the pet heating pads come with a warranty?

A: Absolutely. All our pet heating pads come with a standard 1-year limited warranty covering manufacturing defects. Extended warranty options are available for B2B partners. - Q: Can these pads be used outdoors?

A: Only specific models designated as outdoor pet heating pad with appropriate IP ratings (e.g., IP67) are designed for outdoor use. Indoor models are not recommended for external environments.

Our commitment to partners extends beyond product quality. We offer reliable delivery schedules, with typical lead times for bulk orders ranging from 20 to 35 business days, ensuring timely stock replenishment. Furthermore, all products are backed by a comprehensive warranty, typically a 1-year limited warranty against manufacturing defects, underscoring our confidence in product durability and performance. A dedicated customer support team is readily available to provide technical assistance, address inquiries, and facilitate any post-purchase needs, ensuring a seamless experience for our B2B clients.

Authoritative References

- American Veterinary Medical Association. "Guidelines for the humane care and use of animals."

- International Organization for Standardization (ISO). "Quality management systems - Requirements (ISO 9001)."

- Underwriters Laboratories (UL). "Standard for Safety for Electric Heating Pads (UL 130)."

- The Humane Society of the United States. "Providing Shelter for Outdoor Cats."

- Journal of Veterinary Internal Medicine. "Thermoregulation in Canines and Felines: Clinical Implications."

This is the first article

-

Blue Top Coagulation Blood Test Tubes | Sodium Citrate

NewsAug.12,2025 -

Lithium Heparin Tubes: Fast & Reliable Blood Collection Solutions

NewsAug.11,2025 -

Safe & Effective Pet Heating Pads for Cozy Comfort

NewsAug.10,2025 -

Separator Gel Blood Collection Tubes: Efficient Plasma Separation

NewsAug.09,2025 -

USB Electric Blanket Shawl: Portable Warmth & Comfort

NewsAug.08,2025